Bowstring truss roof repairs and reinforcement

Wood Bowstring Trusses: An architect’s dream that presents special challenges

An architect's dream that presents special challenges

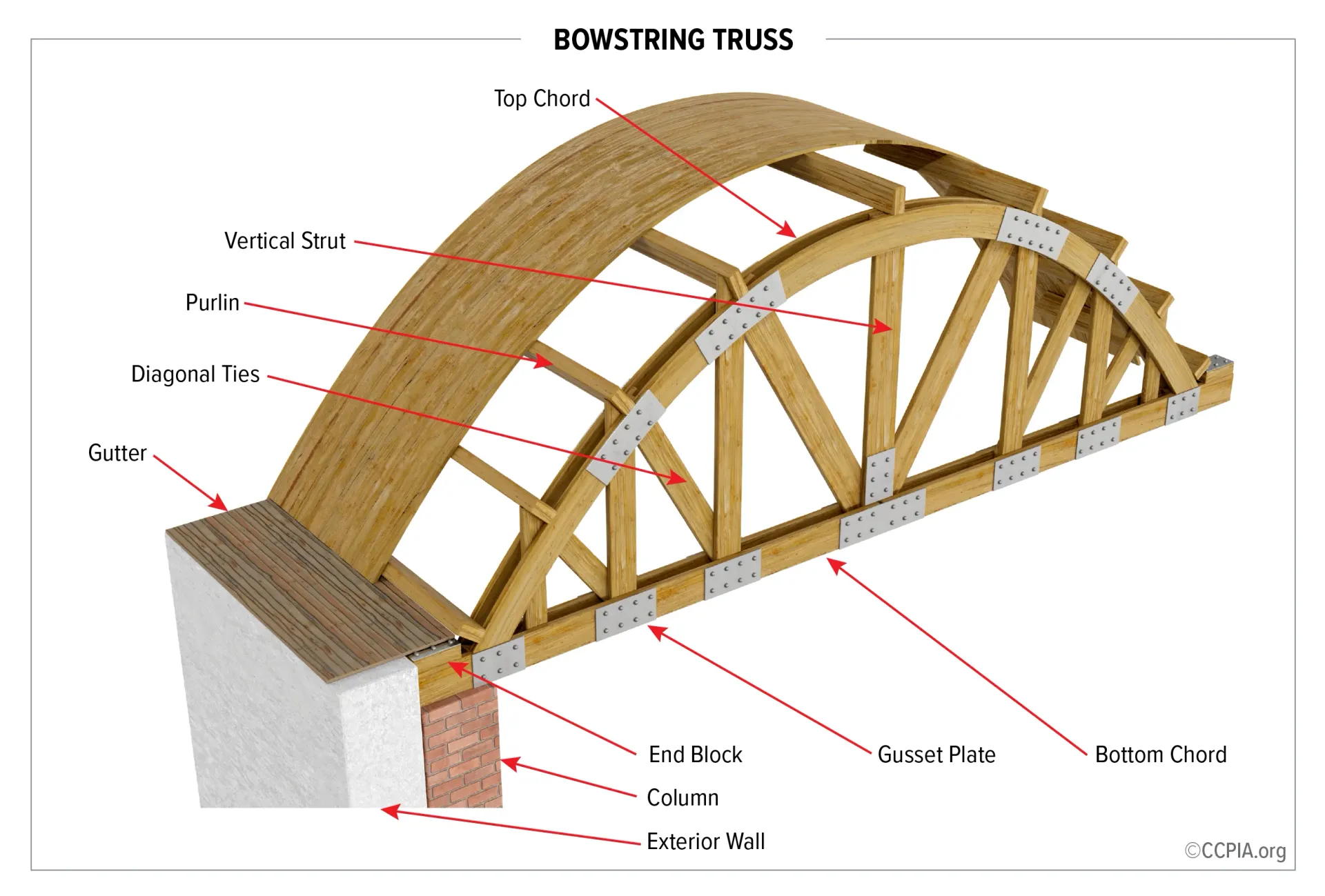

In the 1940s, the wood bowstring truss, with its curved top chord and straight bottom chord, gave architects the ability to design modern, attractive structures with open floor spaces and no columns. These trusses can be found in commercial and institutional buildings across the U.S., particularly in the Midwest. However, bowstring trusses in structures built before 1980 most likely will not meet current code requirements for load capacity.1

No matter their construction date, buildings with wood bowstring trusses present their owners with extra maintenance requirements to avoid failures. Regular inspection — and in some cases, rebuilding or replacement — will be needed. Also, firefighters are often reluctant to enter such buildings due to the risk of roof collapse.

Some practical advice to help avoid a truss failure.

Fortunately, there are steps you can take to help avoid wood bowstring truss failures leading to collapse:

- Have trusses on your building inspected by a licensed or professional structural engineer (designations vary by state) with wood bowstring truss experience. Complete re-inspections by a licensed or professional structural engineer at 5-year intervals.

- Instruct maintenance staff and contractors never to cut, modify or hang equipment from the trusses.

- Clear debris from roof drains and gutters to prevent standing water. Perform this task at least quarterly, or more frequently as needed.

- Institute your own inspection program. At quarterly intervals, look for these conditions:

- Signs of water staining or efflorescence on trusses or masonry supporting walls

- Deformities in the truss or change in the smooth curvature along the top chord

- Cracking anywhere on the wood truss or masonry wall supporting the truss

If any of these conditions are identified, engage a licensed or professional structural engineer to complete a further evaluation.

Reasons why wood bowstring trusses fail.

There are many reasons why these trusses fail. Here’s a brief summary:

- Safety factors for wood stress levels are better understood today than they were in the 1940-1960 time period, when most construction using wood bowstring trusses was completed. As a result, many of these old trusses have been found to be significantly overstressed — possibly by more than a factor of 2.

- The curved top chord allows the buildup of snow and water weight on the roof to cause uneven loading, increasing the stress on the wood members. In turn, the uneven loading can reverse the stress on the wood members causing a “push-pull” situation that weakens the wood joints.

- Wood truss members are compromised by water leaks, due to lack of maintenance, or by the construction methods used in erecting masonry supporting walls.

- Some building owners make improper modifications, such as the addition of roof-mounted mechanical equipment, suspended ceilings or other items not included in the original design.

- Trusses sometimes sustain damage from material-handling equipment (such as forklifts) or cutting/notching of the wood members.

- Structural weakening may be caused by the subsequent addition of a loft with a load-bearing floor, perhaps to create additional storage space, along the bottom chord of the truss.

As indicated on the previous page, if any of these conditions are identified, engage a licensed or professional structural engineer to complete a further evaluation. Wood bowstring trusses can be repaired or rebuilt by experienced contractors. Types of repairs include adding reinforcing wood, lateral supports and/or post tensioning elements.

1 Bowstring Trusses ‘Fail’ to Meet Current Code Requirements, Western Wood Structures White Paper, Paul C. Gilham, Terry D. McKee (2015).

Article shared from Nationwide Insurance.

The information used to create this post was obtained from sources believed to be reliable to help users address their own risk management and insurance needs. It does not and is not intended to provide legal advice.

- Fully licensed and bonded

- Above and Beyond OSHA Standards

Providing top-quality wooden bowstring truss roof repairs for commercial buildings and building contractors. Our trusses are expertly repaired with a keen focus on detail, ensuring that they meet the unique specifications of each project.

CONTACT INFORMATION

Address: Lake Forest, IL United States

Phone: (312) 967-8157

Email: info@woodenroofsolutions.com

All Rights Reserved | WRS - Wooden Roof Solutions LLC. Website by SmallBee.com